Whatever your budget allows, whatever your situation calls for, each and every Castoldi waterjet model has options to suit your requirements. We provide a complete range of fully integrated control systems, from simple mechanical to sophisticated electronic equipped with a joystick docking feature.

REVERSING CONTROL OPTIONS

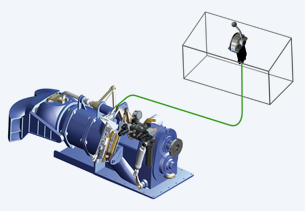

Mechanical/hydraulic

Provides the proportional control (non follow-up) of the reversing bucket actuated by means of a push/pull cable operated by the helm lever.

The helm lever is directly connected to the spool of the hydraulic control valve on the waterjet hydraulic reversing actuator.

The helm lever can be set to any position whether or not the hydraulic system is operating; hence the position of the reversing bucket can be selected prior to the engine start-up.

– Integrated hydraulic components, waterjet mounted

– Use of conventional lever

– No electricity required

– Available for all the models up to TD 490 H.C. included.

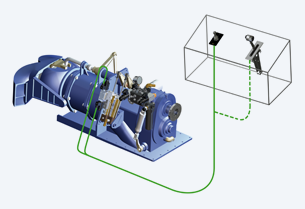

Electric/hydraulic

Provides the on/off control (non-follow up) of the reversing bucket.

Electric cables connect a single axis joystick to a standard hydraulic solenoid valve (CETOP 3), that can be configured to either 12 or 24 volt systems, which in turn is connected to the waterjet hydraulic steering actuator. An indicator is provided to show the steering nozzle position, through its full range of travel.

With this system, rather than having a joystick, it is possible to use a special Castoldi single lever control box, which manages the reversing bucket with a switch and the engine rpm mechanically.

– Integrated hydraulic components and feedback sensors, waterjet mounted

– Cables with plug-in connectors

– Available for all the models.

STEERING CONTROL OPTIONS

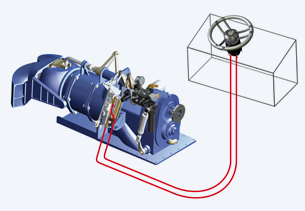

Manual/hydraulic

The helm wheel hydraulic pump (oil self-fed) is directly connected to the waterjet hydraulic steering actuator, through hoses.

In multiple installations a tie rod is required to mechanically synchronize the waterjet steering nozzles.

– Available for all the models up to TD 340 H.C. included (only in single installation).

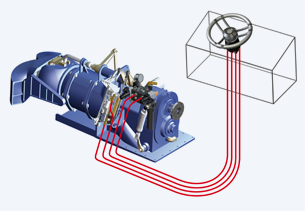

Hydraulic power assisted

The helm wheel hydraulic pump is directly connected to the waterjet hydraulic steering actuator through hoses, but the oil feed is taken from the waterjet integrated gearbox.

In multiple installations it is possible to switch the oil feed from one waterjet to another by means of a dedicated steering feed panel.

In multiple installations a tie rod is required to mechanically synchronize the waterjet steering nozzles.

– Available from TD 282 to TD 340 H.C. included while standard from TD 400 H.C. to TD 600 H.C.T. included.

Electric/hydraulic

Provides the on/off control (non-follow up) of the steering nozzle.

Electric cables connect a single axis joystick to a standard hydraulic solenoid valve (CETOP 3), that can be configured to either 12 or 24 volt systems, which in turn is connected to the waterjet hydraulic steering actuator. An indicator is provided to show the steering nozzle position, through its full range of travel.

In multiple installations a tie rod is required to mechanically synchronize the waterjet steering nozzles.

– Available from TD 282 to TD 600 H.C.T. included.

Electronic

Described in the ACES section.

In multiple installations, the steering nozzles are electronically synchronized (no tie rod required).

ACES Electronic Control System

A modular, software-configurable electronic control system based on modern CAN bus technology. It uses separate microprocessor control units (IP 67) that can be connected in various combinations to build a vessel control system.

– Suitable for single and multiple installations

– Expandable from one to six control stations

– Computerised setup process

– Variety of control devices for different configurations

– Intuitive user interface

– Capable of interfacing with bow thruster, autopilot and dynamic position

– Integrated hydraulic components and feedback sensors, waterjet mounted

– Cables with plug-in connectors

– Separate and independent backup systems provided, depending on the selected configuration

– Available from TD 284 H.C. to TD 600 H.C.T. included.

The system consists of 4 components (IP 67), two available as stand-alone options:

Electronic control box (available as stand-alone option)

Available with a single or twin lever, it manages the engine rpm and the waterjet bucket proportional control. Other functions are available through panel switches for managing the waterjet built-in hydraulic clutch engagement/disengagement, the Clear-Duct unclogging system/grid opening, active driving station (only with multiple stations), and the engine rpm/reversing bucket synchro.

Each lever is also equipped with a booster switch on the upper side, which can be used to accelerate the engine when the bucket is in intermediate positions, to get high thrust at low speed.

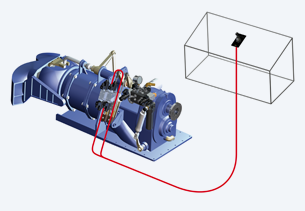

Electronic steering system (available as stand-alone option)

Simplifies the traditional steering hydraulic apparatus by eliminating all hoses running from the helm to the waterjet.

It is equipped with an electromagnetic brake that allows adjustment of torque (hardness), helm rotation (number of turns) and settings to limit nozzle travel.

In multiple installations, the steering nozzles are electronically synchronized (no tie rod required)

Joystick

Designed to assist the operator by simplifying all manoeuvres. Inexperienced boaters will appreciate the simplicity of the “push to go” system, which is more intuitive than conventional controls, while master skippers will appreciate its ease of use for reducing time in docking operations.

The joystick can be moved freely along all its axes and rotated by turning the head.

It also incorporates a backlit switch panel for managing its activation, bow thruster activation (if present) and joystick emergency deactivation.

A wireless version is also available, allowing full control from any position in the boat.

In this configuration, the ACES electronic control system can also be interfaced with:

– Bow thruster

– Autopilot

– Dynamic position.

LCD display

Using simple, intuitive graphics this real-time display shows the steering nozzle and reversing bucket position, engine rpm and vectorial thrust. The same information can also be reproduced on a conventional multi-function display.

PANELS

Clucth/Grid/Clear-Duct

Manages the engagement/disengagement of the waterjet built-in hydraulic clutch on all the HC models except for the TD 240 H.C., which is equipped with a simple activation switch.

Controls the actuation of the movable grid and the Clear-Duct unclogging system (if installed) from TD 284 H.C. up to TD 600 H.C.T. included.

– Not present with the ACES electronic control box.

Oil

Shows the waterjet oil level, pressure and temperature in real-time.

Incorporates alarms for low oil pressure and clogged oil filter.

– Not present with the ACES LCD display

– Standard from TD 340 H.C. to TD 600 H.C.T. included.

Steering feed

Switches the oil feed from one waterjet to another, in multiple installations, when the hydraulic power assisted steering system is installed.

Reversing bucket position indicator

Shows the reversing bucket position, through its full range of travel.

– Not present with the mechanical and mechanical/hydraulic control systems and the ACES LCD display

– Standard on all the models equipped with electric/hydraulic reversing control system.

Steering nozzle position indicator

Shows the steering nozzle position, through its full range of travel.

– Not present with the ACES LCD display

– Standard from TD 340 H.C. up to TD 600 H.C.T. included.